Twin Gantry

M/cs

Turning Machines

MOTORUM

MW100GT

The MW100GT at a Glance

- Shorter Cycle Times

The MW100GT is a twin spindle, dual gantry CNC turning center that can reduce cycle time by half.

- Improved Productivity

The MW100GT is designed to provide exceptional rigidity and high-precision processing for increased productivity.

- Compact Size

Its compact design makes it the perfect solution for line planning, as well as for saving space in production.

| Basic Machine Specifications | MW100GT |

|---|---|

| Maximum Chuck Size | 165 mm |

| Total Machine Weight | 3,600.0 kg |

| Spindle Nose Size | JIS A2-5 |

| Standard Load Time | 6.0 Seconds |

MOTORUM

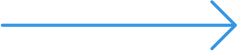

MW120GT

16 seconds–that’s the production time required for the MW120GT. In addition to minimum production time, this machine was designed with a twin gantry loader to reduce cycle time and improve productivity. As a self-contained machine, the MW120GT offers all of the turning capabilities you need, from a single source.

Equipped with a twin gantry, the MW120GT is a twin spindle CNC turning center that optimizes production time. This machine is all about speed, and both its high-speed gantry loader and turret axes help to reduce cycle time drastically. Unlike similar models on the market, the MW120GT is entirely self-contained, allowing operators to turn highly accurate parts from a single source machine.

The MW120GT at a Glance

- Shorter Cycle Times

The MW100GT is a twin spindle, dual gantry CNC turning center that can reduce cycle time by half.

- Improved Productivity

The MW100GT is designed to provide exceptional rigidity and high-precision processing for increased productivity.

- Compact Size

Its compact design makes it the perfect solution for line planning, as well as for saving space in production.

| Basic Machine Specifications | MW100GT |

|---|---|

| Maximum Chuck Size | 210mm |

| Total Machine Weight | 3,600.0 kg |

| Spindle Nose Size | JIS A2-5 |

| Standard Load Time | 6.0 Seconds |

MOTORUM

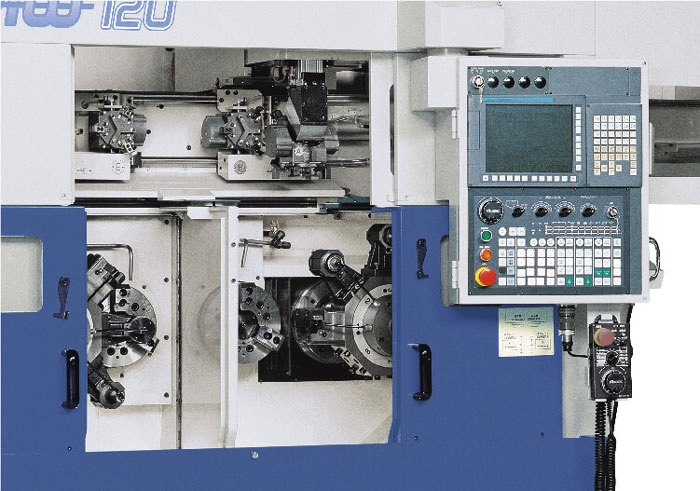

MW200GT

For faster cycle times and exceptional rigidity on larger parts, look no further than the MW200GT. With a twin, three-axis gantry loader, this machine offers versatile solutions and reduces cycle time in half with its dual operating spindles.

The MW200GT is a twin spindle, CNC turning center with twin gantries. In fact, its twin, three-axis gantry loader enables it to be an incredibly versatile machine by allowing for quick loading/unloading at stocker systems, conveyors and beyond. Designed with a column/turret bar construction, the MW200GT provides world-class rigidity and high precision processing for a greater level of productivity.

When it comes to high-precision processing, increased productivity, and shorter cycle times, the MW200GT is a CNC turning center that truly delivers.

The MW200GT at a Glance

- Shorter Cycle Times

The MW100GT is a twin spindle, dual gantry CNC turning center that can reduce cycle time by half.

- Improved Productivity

The MW100GT is designed to provide exceptional rigidity and high-precision processing for increased productivity.

- Compact Size

Its compact design makes it the perfect solution for line planning, as well as for saving space in production.

| Basic Machine Specifications | MW200GT |

|---|---|

| Maximum Chuck Size | 254mm |

| Maximum Spindle Speed | 3500 rpm kg |

| Spindle Drive Motor | 20kW/30 min |

| Gantry Handling Capacity | MW200 – Ø200mm x 120mm |

Looking for support?

Identify the right solution for your specific requirement Quis

Improve warehouse safety with automated material handling.

Our technical team is always reedy to answer your quires Null

Review the benefits of automated warehouse solutions in semiconductor environments.