Muratec Machine Tool Series

Turning Machines

MW Series

When it comes to speed, reliability, accuracy, flexibility, precision, repeatability, Muratec MW machines become the backbone of automotive parts suppliers’ production lines.

The ease of use and adaptability, allows MW machines for running medium to high volume prod[uctions. This series also includes the inline gauging, and other peripherals necessary for the machining process. This is one of the most versatile series in the Muratec line up which helps you manufacture high quality, high profitability parts.

MS Series

These machines are efficient and reliable and can increase productivity while decreasing the overall cost of labour.

Muratec single spindle machines are great job shop workhorses or drop one into your production line for an additional operation.

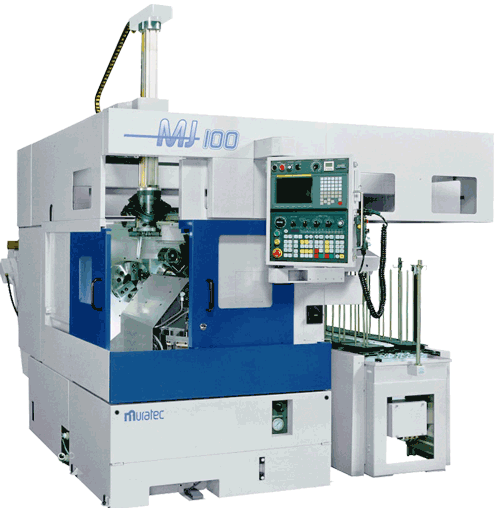

MJ Series

Muratec specialty machines are made up of our MJ and ML series and are designed to turn medium and longer than usual parts to achieve higher profitability and productivity at lower costs.

Each of the machines in our MJ series is equipped with a tailstock, which reduces the movement of both the part and the machine. The MJ machines handle tighter tolerances to deliver greater centricity precision, and their compact size makes them the ideal fit for facilities seeking to save space in production.

MD Series

The MD Series machines feature automated CNC turning centres with live-tooling capabilities, including drilling & milling. These machines efficiently meet low & high-volume production requirements by combining multiple operations into a single machine.

These machines can efficiently meet low and high-volume production requirements by combining multiple operations into a single machine. With our integrated 3-Axis gantry robot loader and compact machine footprint, the MD Series machines support reduced labour costs and efficient production space planning for your facility.

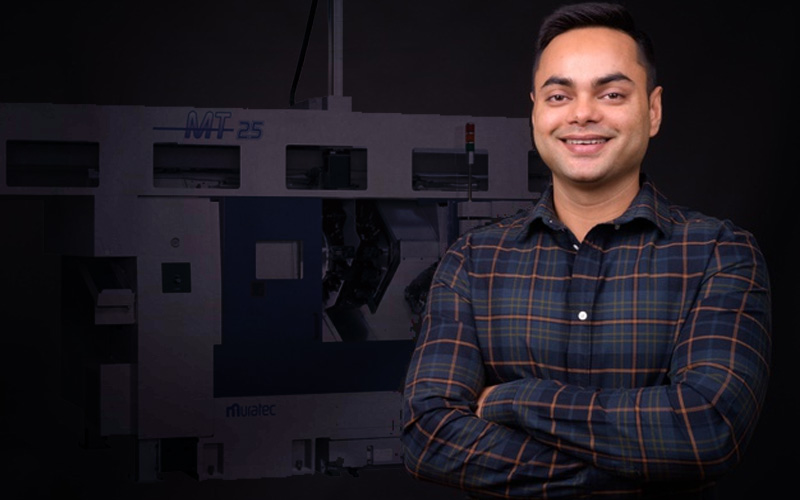

MT Series

Often referred to as a job shop in a box,’ the twin opposing spindle turning machine in our MT Series can come equipped with up to 15 cutting tool stations per turret, with varying flexibility.

Multi-tasking capabilities offer Flexible Automation: an all-in-one solution with bar and chuck capabilities, High Multi-functional performance for Mass production.

This machine can handle Large-size Bar work Handling (MT200 Max. Ø80mm Left Spindle)

MT series offers Selectable Spindle Drive Motors and Speed Ranges; Y-axis on All Turrets is a standard function. The live tool is available on all Turrets and Stations, Comes with a New High-Speed 3-axis CNC Gantry Loader.