Trusted Solution provider for high-end & high Efficiency machines

Company Profile

Started in 2004 by A.V. Srinivasan along with Muratec, Meiban Engg has been in existence for 17 years and has achieved a consistent growth and received accolades from customers, which includes a best supplier award from a multi-national company.

Meiban Engineering Technologies Pvt Ltd is a solution provider in the field of Automation and Turnkey projects for manufacturing Automobile and sheet metal components. Meiban Engg. supplies and services sheet metal machines which include CNC Servo Turret Punch presses of various capacities, punching and shearing machines.

In the metal cutting division, Meiban Engg serves with high end automated twin spindle chuckers for manufacturing Automotive components, hydraulic components and bearing components.

Meiban Engg has started the localisation of Muratec turning machines on both machine and application side. Meiban Engg prides itself in being the end to end supplier for both sheet metal and turned parts from simple to sophisticated automation solutions.

History

2004

Meiban Engineering founded in Bangalore

2006

Metal Cutting Division started

2007

Rittal Best Supplier Award

2008

Chennai Sales Office and Mumbai Sales Resident Engineer

2011

Our Tech Center and full-fledged office with Demo machines & show room started in Bangalore

2013

Local turnkey base work started

2014

Delhi Sales & Service branch and Mumbai Service

2015

First local turnkey of turning machines delivered

2021

Pune Sales & Service Resident Engineer

Establishment of Unit-II for TKC operations

Vision

"

Mission

We will constantly strive for profitable and meaningful growth by following the initiatives needed to achieve our vision. We will seek to achieve operational excellence in every task we undertake to fulfil the company’s short & long-term goals by providing our customers with sustainable, reliable and smart manufacturing solutions.

Message from our Chairman

Murata Machinery has been providing customers with solutions, including but not limited to equipment, throughout the world. That means what we provide to the customers are machines, peripheral equipment, tooling, software, installation, training, field service, consultation and any other things required for the customers to utilize our equipment in the best way for their operation. Meiban Engineering Technologies is a crucial partner to provide solutions to customers in India. In the last 10years, it has gained substantial amount of capability supported by our customers in India. We will continuously grow with our customers to serve them, providing better solutions.

Mr Yosuke Murata

CHAIRMAN

Message from CEO

“Celebrating our Company’s 17th anniversary gives me immense pleasure and fills me with a lot of gratitude for our Customers, Employees and our Partner “Muratec”, Japan. Our goal of constant improvement might change things the way we do, but our commitment to” Smart Customer Support” remains as strong as ever.

We will constantly strive for profitable and meaningful growth by following the initiatives needed to achieve our vision. We will seek to achieve operational excellence in every task we undertake to fulfil the short & long-term goals of the company by providing our customers with sustainable, reliable and smart manufacturing solutions.

Mr. A.V. Srinivasan

CEO

Meiban Muratec

Tech Centre

Meiban Engineering Technologies Pvt. Ltd, Head Office in Bangalore, has its network spread all over India to cater to customer needs. A strong workforce, specially trained in Muratec, Japan, helps provide total solutions to the customer.

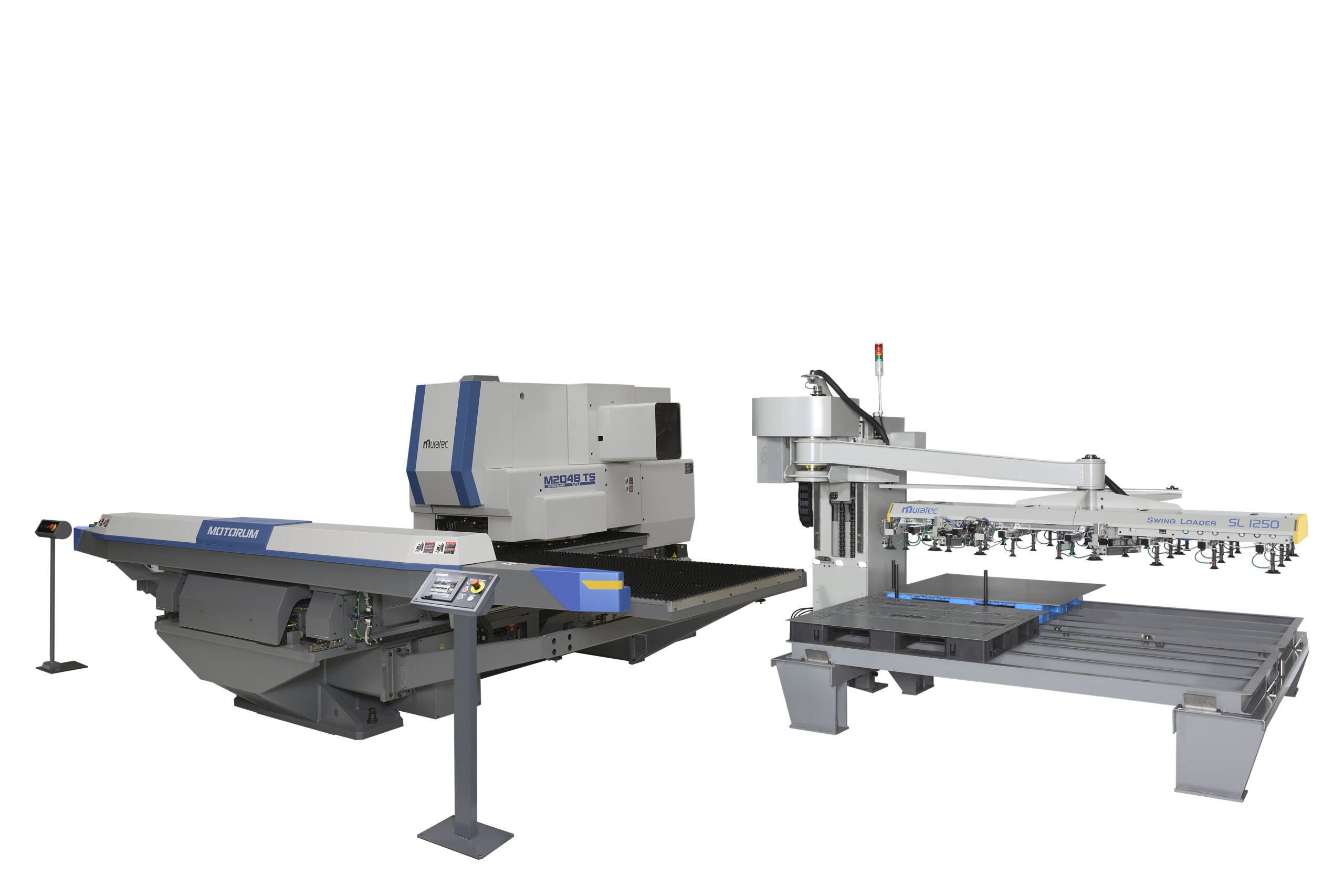

Technology Centre features Muratec’s best-selling MW series MW100HGL and MW120HGL for Customer demos and test cuts, and Motorum 2048TS with SL2512 Loader System, Servo Press Brakes in 40 & 60 ton capacities. Meiban Engineering Technology Pvt. Ltd Centre showcases the latest advanced and proven solutions to demonstrate the technical solutions to customers. Technology Centre is the central location for Spare parts, training Academy & online telephone support Centre. Centrally Located Technical Centre are easily accessible to customers. Meiban Technical Centre is equipped to provide the following customer support activities.

- Turnkey Solutions

- Application Support

- Technical Proposals

- Service Support

- Customer Training

- Machine Shifting

- Retooling

- Machine Reconditioning

MW100 Twin

Spindle CNC

Chucker

MW120 Twin

Spindle CNC

Chucker

Turnkey Solutions

Muratec has established itself as a strong player in offering total turnkey solutions, which include suitable from process selection to time study preparation to a selection of tooling and chucks to prove out at the Technology Centre and Customers place.

Turnkey Activities Include

Provide appropriate Turning and Turnmill engineering solutions for the benefit of the customer and feasibility study.

Selection of the most suitable machine & time study estimation by studying component drawing

Testcut and proveout of components

Provide end-to-end Turn-Key solutions for component machining from various industries like automobile, general engineering, pump industry, etc.

Suggest the most suitable & cost-efficient process to improve productivity, quality & reduce the cycle time.

On-site machine operating & programming training.

Arrange training programs at the technology centre to educate the customer

Sheet Metal

Demonstration and Training Center in Bangalore

- Latest AC Servo Turret Punch Press ive demonstration

- Real time Punching Cycle time study

- ProcessNet-i online monitoring through web

- CAMPTH G4 Advanced software demonstration

Campath G4

(CAD/CAM system for TPP)

Training School

G4 is “All-Round” CAD/CAM software that is easy to operate and designed to work alongside the Windows operating system. The software also incorporates many latest features like Nesting, 3D-unfolding etc.

These courses are meant for your engineers in Operations, Programming or Design. We have been providing this knowledge of CAMPATH to Muratec Turret Punch Press users. So far, we have trained all our existing customers. Earlier participants have given feedback on the direct benefits of the course in terms of reduced punching cycle time, better optimization, increased productivity etc.

Methodology

The faculty comprises 17 years of experienced engineers trained abroad and Sheet metal product manufacturing experienced. We employ the latest training methods to make the training most effective.

Our Associate

Companies

P&B Manufacturing Pvt. Ltd.

Our Logo

Meiban Engineering Technologies Pvt Ltd

The logo is a registered

trademark of Meiban

Engineering Technologies Pvt. Ltd

Murata Machinery Limited, Japan

The logo is a registered

trademark of Murata

Machinery, LTD. Japan