Hybrid Combination Machine

sheet metal machines

Hybrid Punch Laser

MF3048HL

All the benefits of turret punch press with fiber laser integration are available in one machine.

- Features

Increased productivity

Greater manufacturing flexibility & tolerances due to single work piece clamping.

Faster processing & higher ROI due to reduced number of processes and machines.

| Main Specifications | MF3048HL |

|---|---|

| Punching capacity | 300 kN 30.6 Metric Tons 33.6 US Tons |

| Laser capacity | 3000W |

| Tapping unit | 4 (standard), 8 (option) |

| Maximum sheet size without repositioning (Y x X) | 1525 mm × 2500 mm | Maximum sheet thickness | 6.35mm |

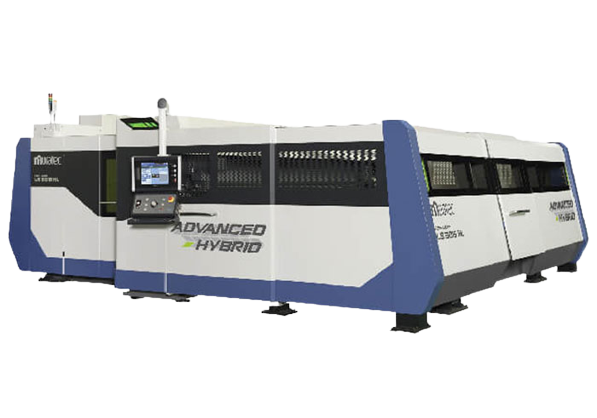

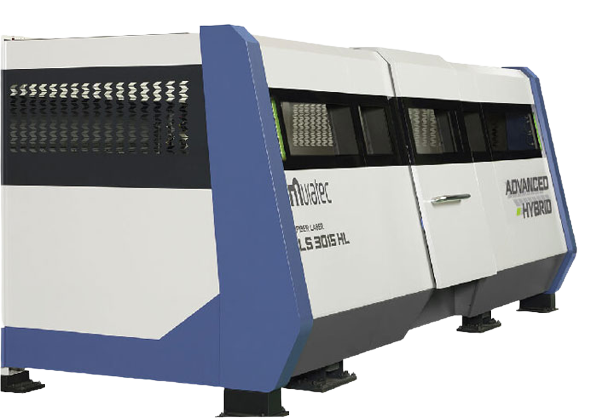

Advanced Hybrid Laser

LS3015HL

Features

- New Hybrid machine with fiber laser basis

In order to achieve the most value from the fiber laser system, material is processed on traditional slat pallets using flying optics providing high speed and high accuracy.

- Forming Operations by Servo Drive

Support for various forming processes is done with upper and lower servo drives. Forming operations are performed on a stable brush table. Tool conditions in the control allow adjustment of all forming profiles.

- High Quality Rigid Tapping Unit driven by servo motor

Servo-controlled tapping supports a large variety of machine and roll-type taps. Automatic chip vacuum, tap lubrication, tap breakage sensor and tap life management is included.

- Table Shift

The material is moved from slats pallet to brush table by a fork unit. Provides seamless table shift transfer from cutting to forming. Designed to maintain quality throughout cutting and forming processes, the fork unit transfers material from the laser pallet to the brush table, utilizing work clamps to keep the material from shifting during transition.

| Main Specifications | LS3015HL |

|---|---|

| Rated Output | 2500 W, 4000 W, 6000 W |

| Maximum Cutting Area (XxYxZ) | 3075mm x 1550mm x 100mm |

| Maximum Material weight | 920 kg Automation 600 kg |

| Fast traverse speed | 170 m/min (XY simultaneous) |

| Positioning accuracy | +/- 0.01 mm |

| Repeat Accuracy | +/- 0.01 mm |