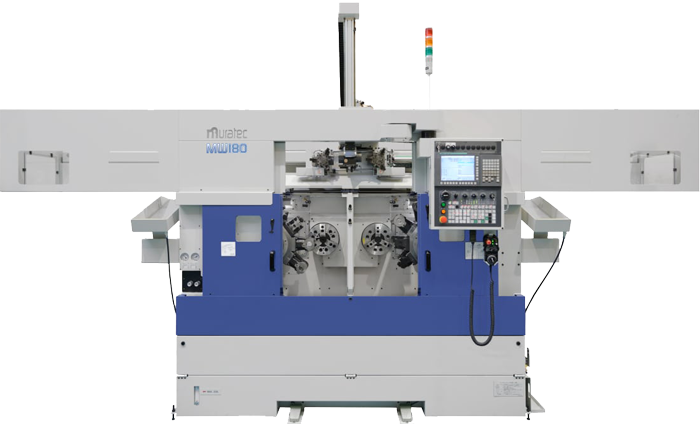

MW 180 / 200 Series

Turning Machines

MOTORUM

MW180

The MW180 at a Glance

- Flexible Machine Utilization

The MW180 has the ability to offer flexible machine utilization for two simultaneous processes, as well as turnaround applications.

- Delivers Versatility

Available with a single or dual gantry robot loader, the MW180 can pick up parts of varying sizes and weights for added versatility to meet various production time requirements.

- Self-Contained

The MW180 is a self-contained machine, and all operations are integral to this machine for optimal flexibility and improved productivity.

| Basic Machine Specifications | MW180 |

|---|---|

| Maximum Chuck Size | 254 mm |

| Number of Turret Stations | 10 x 2 |

| Maximum Spindle Speed | 3500 rpm |

| Spindle Drive Motor | 15 kW/30 min |

| Total Machine Weight (Approx.) | 7200 kg |

| Gantry Handling Capacity | Φ180 mm x 80 mm , up to 3.0kg/piece |

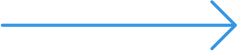

MOTORUM

MW200

The MW200 at a Glance

- Flexible Machine Utilization

The MW200 offers ultimate flexibility for performing two identical cutting processes or turnaround cutting applications in a 10” chuck machine.

- Delivers Versatility

Available with a single, or twin gantry loaders, the MW200 can load/unload various sizes and weights for added versatility to meet all production time requirements.

- Self-Contained

The MW200 is a self-contained machine, and all operations are integral to this machine for optimal flexibility and improved productivity.

| Basic Machine Specifications | MW200 |

|---|---|

| Maximum Chuck Size | 254 mm |

| Number of Turret Stations | 10 x 2 |

| Maximum Spindle Speed | 3500 rpm |

| Spindle Drive Motor | 15 kW/30 min |

| Total Machine Weight (Approx.) | 7200 kg |

| Gantry Handling Capacity | Φ180 mm x 80 mm , up to 3.0kg/piece |

Looking for support?

Identify the right solution for your specific requirement Quis

Improve warehouse safety with automated material handling.

Our technical team is always reedy to answer your quires Null

Review the benefits of automated warehouse solutions in semiconductor environments.