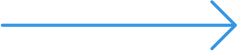

Linear Tooling Concepts

Turning Machines

MOTORUM

MW50

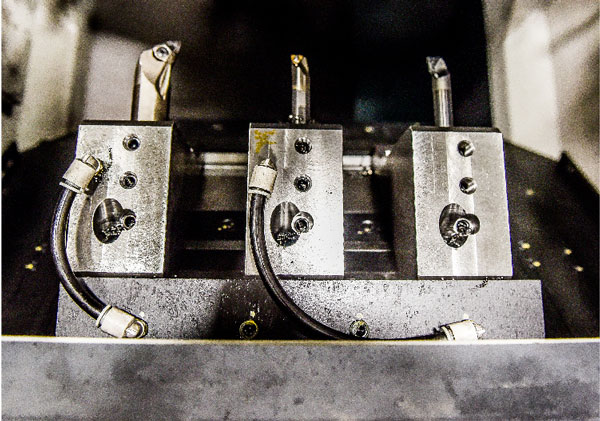

The compact, energy saving MW50 was developed to turn smaller parts with faster cycle times. Featuring two horizontal spindles, this machine can come equipped with one, or two of our high-speed gantry loaders.

All machines in the MW Series are equipped with two spindles, which allows them to turn parts at a fast pace. Designed specifically to turn smaller parts, the MW50 reduces overall cycle time with its high-speed gantry, fast load/unload times, and reduced machine idle time. The MW50 delivers flexibility, versatility and a gang style tooling block for quick tool changes.

The MW120EX at a Glance

- Super High Precision Turning

The MW120EX offers super-high precision turning, performing hard turning at a higher level of accuracy, without grinding.

- Improved Productivity

Available with a single or dual gantry loader for higher productivity, the MW120EX delivers a minimum production time of just 16 seconds.

- Exceptional Rigidity

The MW120EX provides exceptional rigidity for tight tolerance part requirements.

| Basic Machine Specifications | MW50 |

|---|---|

| Maximum Chuck Size | 165 mm |

| Number of Turret Stations | Tool Plate x 2, Width: 270mm |

| Maximum Spindle Speed | 6000 rpm *No option |

| Spindle Drive Motor | 7.5 kW /30 min *No option |

| Total Machine Weight (Approx.) | 3400 kg |

| Gantry Handling Capacity | Φ50 mm x 50 mm , up to 0.5kg/piece |

| Spindle Nose Size | Flat nose |

| Spindle Nose Size | X-axis 18 m/min | Z-axis 24 m/min |

MOTORUM

MW80

As a super-compact twin spindle turning center, the MW80 reduces cycle times with its high-speed gantry and lightning-fast load/unload times. Designed for increased productivity, this machine is equipped with two horizontal spindles and twin four-station tool blocks. Though it has the same gantry speed as the MW50, the MW80 can accommodate slightly larger parts.

Boasting speeds of up to 6,000 RPM, the MW80 is the ultimate solution for the turning of high-speed parts. It’s a dual spindle turning machine and is built with two of Muratec’s proven high-speed gantry loaders, a feature that increases uptime and reduces overall cycle times. This machine is also incredibly flexible and has a wide gang tool platform for added versatility.

Delivering high speeds, shorter cycle time and reduced idle times, the MW80 is an optimal solution for high-speed turning.

The MW80 at a Glance

- High-Speed Processing

Available with a twin gantry for high-speed processing of parts up to 80 mm in diameter.

- Shorter Cycle Times

With its high-speed gantry, fast load/unload times, and reduced cycle times, the MW80 delivers shorter cycle times.

- Flexible Machining

The MW80 is incredibly flexible and has a wide gang tool platform for added versatility.

| Basic Machine Specifications | MW80 |

|---|---|

| Maximum Chuck Size | 165 mm |

| Number of Turret Stations | Tool Plate x 2, Width: 370mm |

| Maximum Spindle Speed | 6000 rpm *No option |

| Spindle Drive Motor | 7.5 kW /30 min *No option |

| Total Machine Weight (Approx.) | 4000 kg |

| Gantry Handling Capacity | Φ80 mm x 50 mm , up to 0.5kg/piece |

| Spindle Nose Size | Flat nose |

| Spindle Nose Size | X-axis 18 m/min | Z-axis 18 m/min |

Looking for support?

Identify the right solution for your specific requirement Quis

Improve warehouse safety with automated material handling.

Our technical team is always reedy to answer your quires Null

Review the benefits of automated warehouse solutions in semiconductor environments.